Production Flow Diagram Of Stone Crushing Plant Jaw Crusher

The cycle of crushing process of the

Download scientific diagram The cycle of crushing process of the Jaw crusher plant from publication: Automated process control system of Jaw crusher production Rocks go throughThe flow chart for the process is shown below Firstly, the big raw materials are evenly sent to jaw crusher by vibrating feeder for coarse crushing, and the coarsely crushed materials are sent to Process flow chart for stone crushing plant cmcrusherIn this article, we will discuss the process flow chart for stone crushing plant The first stage of the crushing process is the primary crushing In this stage, the raw materials are fed into the jaw process flow chart for stone crushing plantⅠBrief introduction of flow chart for stone production line Firstly, stones are transferred to primary crusher throught vibrating feeder for first crushing, then the crushed materials are transferred to impact crusher through belt Stone Production LineStone Making

.jpg)

150TPH to 200TPH stone crusher plant design and

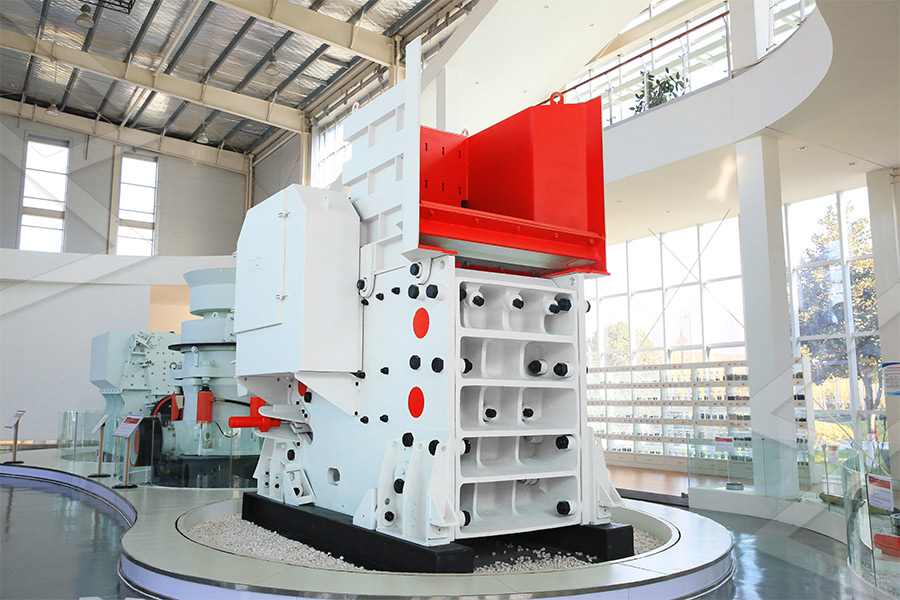

Flow chart of stone crushing plant: SBM 150 TPH 200 TPH Stone Crusher Plant are designed with ZSW420X110 Vibrating Feeder, PE750X1060 Jaw crusher, PF1315 Impact crusher, 2016年3月11日 The majority of crushing plants recently constructed have accomplished this desired efficiency by optimizing plant design, crusher design and automation By improved efficiency a decrease in energy consumption Crushing Plant Flowsheet DesignLayoutDetails of Machinery used in stone crushing plant Feeding Hopper The function of the hopper is that it collects the raw material and provide required size stone to the Jaw crusher such that big pieces of raw materials into smaller one Shows Process flow Diagram of a typical 2: Schematic illustration of a jaw crusher by J Quist Modeling and simulation is a tool to explore and increase the understanding of a phenomenon This thesis focuses on developing models of2: Schematic illustration of a jaw

How To Make A Flow Chart Of A Crushing Plant

In this article, we will be discussing how to create a flow chart of a crushing plant The first step in creating a flow chart of a crushing plant is to identify the key processes involved in the plant's 2022年2月22日 DSMAC Stone Crushing plant includes vibrating feeder, jaw crusher, impact crusher or cone crusher, vibrating screen, belt conveyor and centrally electric controlling system, etc The designed capacity is from 40t/h Stone Crushing Plant, aggregate crushing 2024年2月18日 The machinery’s highimpact movement typically relates to a high production rate in a primary crusher For instance, a standard jaw crusher diagram might show a feed Jaw Crusher Diagram: Simplified 2022年2月22日 The Stone production line is suitable for crushing granite, river gravel, and limestone and so onThe Stone production line consists of vibrating feeder, jaw crusher, impact crusher, and vibrating screen and so on The Big Stone Crushing Plant, aggregate crushing

Layout of a fourstage crushing plant for ballast production

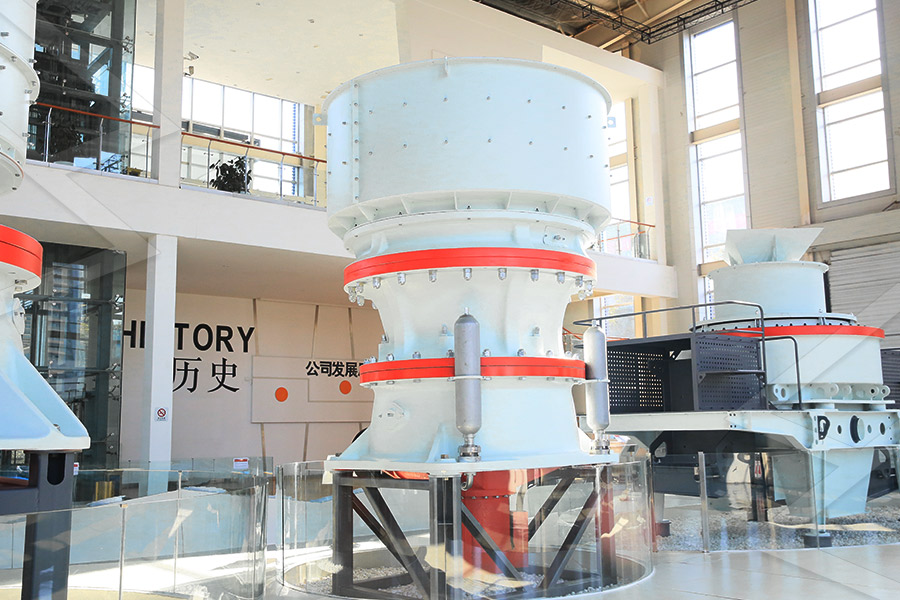

Download scientific diagram Layout of a fourstage crushing plant for ballast production from publication: Cone Crusher Performance PhD Thesis Cone crushers are used by both the 2020年2月8日 This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone The L18 orthogonal array Aggregate Production Optimization in a StoneCrushing Plant 2023年3月2日 The stone crushing plant is mainly composed of a vibrating feeder, jaw crusher, impact crusher, cone crusher, vibrating screen, belt conveyor, a centralized electrical control cabinet, and other auxiliary Getting To Know The Complete Set Stone Tunstall and Bearman (1997) determined the effect of the size distribution on crushinggrinding operations and proposed that feeder material maximal dimension must be 75 – 80 % of inlet General flow chart belonging to the

500TPH600 TPH stone crushing plant with cone crusher

This series stone crushing plant consists of large scale jaw crusher, heavy duty cone crusher, vibrating feeder, vibrating screen, belt conveyor and other auxiliary equipment Flow chart of In this article, we will discuss the process flow chart for stone crushing plant The first stage of the crushing process is the primary crushing In this stage, the raw materials are fed into the jaw process flow chart for stone crushing plantSBM Machinery has designed jaw cone crushing plant, jaw impactor crushing plant for hard, medium hard minerals Flow chart of stone crushing plant: SBM design 80TPH 120TPH 80tph, 120tph Hard rock medium scale rock crushing plant Flow chart of 500 TPH crushing plant – Quarry Machine,Stone Flow chart of 500 TPH crushing plant Mining Equipment of 500 T/H plant list Hopper : LC4000 * 4000 /1 set; Vibrating feeder: Crushing Operation Flowchart Crusher Mills, Cone Crusher, Jaw

.jpg)

Flowchart Diagram Of How Stone Crushers Work Crusher

stone crushing technology introduction and flowchart diagram of building stone process flow production line of building stones how does jaw crusher works; flow diagram for quarry 2019年10月25日 This research includes optimization of aggregate production of the stone crushing plant using fuzzy modelling The investigation includes onsite aggregate testing and Optimization and Simulation of Operation Performance in Crushing Plants Process Flow Chart of Aggregate crushing Plant liming aggregate crusher plant consists of vibrating feeder, heavy duty jaw crusher, small jaw crusher, aggregate crushing process Aggregates Crushing Plant Process Flowchart Crusher Mills2023年2月7日 Flow Chart of 100150TPH Hard Stone Crushing Plant,Materials: Hard Stones,Max Feeding Size: 500mm,Final Product Size: 05, 510, 1020, 2030mm,Capacity: Flow Chart of 100150TPH Hard Stone Crushing Plant

.jpg)

Process flow chart for stone crushing plant cmcrusher

A stone crushing plant is a multistage process that involves various stages of crushing and screening to produce a range of final products The flow chart for the process is shown below 2021年12月3日 With the fast demands on stone crushers, more and more clients inquire cone crusher in crushing plant Great Wall Company is one of leading stone crusher What are application and flow chart of stone crusher in crushing plant?2023年10月16日 Maintenance Tips for Your Jaw Crusher – How to Ensure Optimal Performance and Longevity After understanding the jaw crusher working principle, we need to know some The Mechanics of Crushing: Understanding the Jaw Crusher Stone Crushing plant with production capacity from 80120 TPH is suitable for small scale production line SBM Machinery has designed jaw cone crushing plant, jaw impactor crushing plant for hard, medium hard minerals Flow 80TPH 120TPH Stone Crusher Plant unisbm

Crushing and Screening Handbook AusIMM

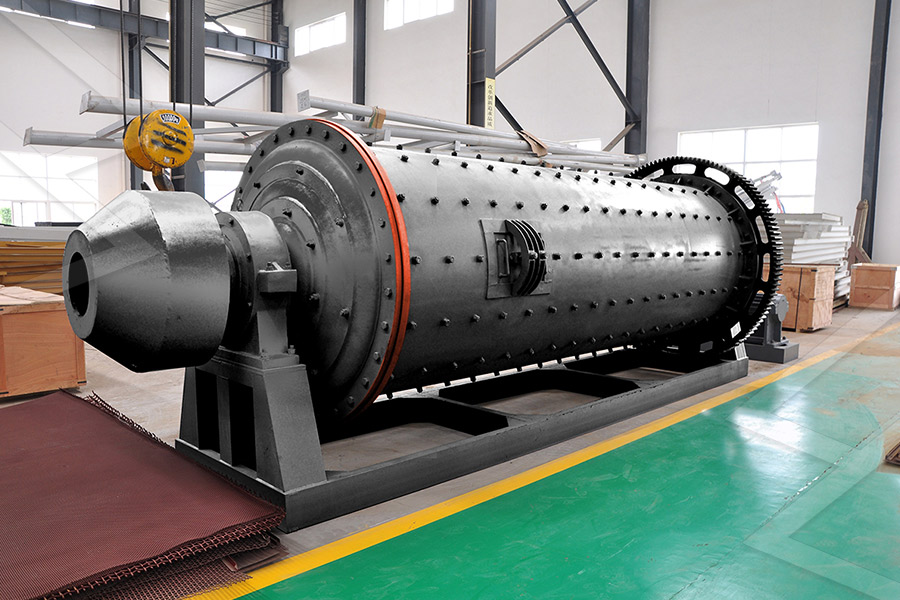

2021年6月24日 TABLE OF CONTENTS Chapter Subject / section name Preface Table of Contents Metso’s Mining and Construction Technology 1 Quarry Process + Process This unit 800TPH1000TPH stone crusher plant which consists of jaw crusher, cone crusher, VSI crusher is widely adopted by companies in large road, bridge construction company, Large scale stone crusher plant from 800 1000 TPH unisbm3 天之前 Crawler mobile crushing and screening station, also called track rock crushing plant or track mounted stone crushing plant, is the most advanced crushing and screening station, High Capacity Tracked Mobile Stone Crusher, Portable 2019年11月29日 Aggregate Production Flow Chart 09:54:52 Aggregate plant includes vibrating feeder, jaw crusher, impact crusher, sand making machine, mobile crusher, Aggregate Production Flow Chart, Aggregate Crushing

Stone Crusher Plant Crushing Kinds Of Stones AIMIX

2024年12月16日 The primary jaw crusher for sale is near the quarry to shorten hauling Belts connect parts for smooth material flow A second crusher processes bigger stones Screens 2014年1月4日 The required capacity defines the size and type of crushing equipment and also the number of parallel crushers or plants required to meet the mine?s production rate Below the surface: Setting up an underground primary jaw crusherExcavate and transfer the raw material into the plant Material is reduced in a jaw crusher Material is screened either to the next screen or to a crusher for further reduction Material is further My Plant Planner MetsoFigure 1: Shows Process flow Diagram of a typical Crush Plant List of machinery and its salient feature for the stone crushing unit which are used in the project duringEnvironmental Impact Assessment of a typical Stone

APJ6090E Jaw Crusher In The Russian Stone Production Line

2025年1月6日 It has not been updated for a while, this time I brought a case of a single jaw crusher A customer from Russia purchased a jaw crusher from AIMIX, model APJ6090EThis Stone crushing plants are used to break down stones of different sizes into smaller pieces or dust in order to make them more usable for various purposes These plants are usually equipped stone crushing flow chart2024年2月18日 The machinery’s highimpact movement typically relates to a high production rate in a primary crusher For instance, a standard jaw crusher diagram might show a feed Jaw Crusher Diagram: Simplified 2022年2月22日 The Stone production line is suitable for crushing granite, river gravel, and limestone and so onThe Stone production line consists of vibrating feeder, jaw crusher, impact crusher, and vibrating screen and so on The Big Stone Crushing Plant, aggregate crushing

.jpg)

Layout of a fourstage crushing plant for ballast production

Download scientific diagram Layout of a fourstage crushing plant for ballast production from publication: Cone Crusher Performance PhD Thesis Cone crushers are used by both the 2020年2月8日 This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone The L18 orthogonal array Aggregate Production Optimization in a StoneCrushing Plant 2023年3月2日 The stone crushing plant is mainly composed of a vibrating feeder, jaw crusher, impact crusher, cone crusher, vibrating screen, belt conveyor, a centralized electrical control cabinet, and other auxiliary Getting To Know The Complete Set Stone Tunstall and Bearman (1997) determined the effect of the size distribution on crushinggrinding operations and proposed that feeder material maximal dimension must be 75 – 80 % of inlet General flow chart belonging to the

.jpg)

500TPH600 TPH stone crushing plant with cone crusher

This series stone crushing plant consists of large scale jaw crusher, heavy duty cone crusher, vibrating feeder, vibrating screen, belt conveyor and other auxiliary equipment Flow chart of In this article, we will discuss the process flow chart for stone crushing plant The first stage of the crushing process is the primary crushing In this stage, the raw materials are fed into the jaw process flow chart for stone crushing plantSBM Machinery has designed jaw cone crushing plant, jaw impactor crushing plant for hard, medium hard minerals Flow chart of stone crushing plant: SBM design 80TPH 120TPH 80tph, 120tph Hard rock medium scale rock crushing plant